Offshore operations at MeyGen’s tidal array

Last month, EMEC were invited to join the MeyGen and Proteus Marine Renewables teams to observe a series of offshore operations in the Pentland Firth. The campaign involved cable works, turbine recovery and re-installation, maintenance and upgrades, providing a valuable opportunity to see a tidal energy array in action and experience firsthand how offshore activities are delivered at sites beyond EMEC.

MeyGen has been operating a 6 MW tidal energy array in the Pentland Firth since 2018, with earlier iterations of the tidal turbines tested at EMEC’s Fall of Warness demonstration site in Orkney. This visit builds on our long‑standing collaboration including a reciprocal visit to the Fall of Warness last year, alongside recent joint industry-wide efforts to address consenting challenges and accelerate progress through the Marine Energy Taskforce.

On board from EMEC were Senior Technical Project Manager, Heather Turnbull, and Marine Operations Specialist, Florence Ungaro. In this blog, Heather shares an inside look at the offshore operations, reflecting on industry progress, EMEC’s legacy in tidal innovation, and the vital role collaboration and knowledge exchange play in driving the commercialisation of tidal energy. This comes at a pivotal time as EMEC prepares for expansion of our own tidal energy facilities to support the sector’s transition to multi-device arrays.

In December, I had the opportunity to join offshore operations at the MeyGen site in the Pentland Firth, an experience that offered a valuable window into how far the tidal energy sector has come and where it is heading next, and, as a bonus, the trip even treated us to a glimpse of the northern lights dancing over the Pentland Firth.

For EMEC, supporting technology development is part of our DNA. Over the past 20 years we’ve seen early concepts mature into grid‑connected turbines, subsea systems, operational procedures and digital tools that are now shaping the first tidal energy arrays. Observing the MeyGen and Proteus teams in action provided a tangible reminder of that journey.

A front‑row view of industry maturity

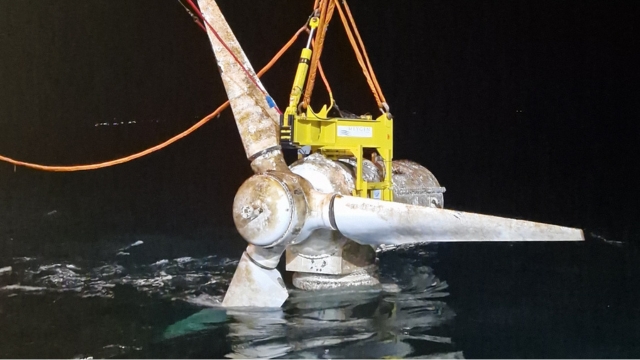

Across several days offshore, we were able to observe a packed programme of activity including subsea cable operations, turbine recovery, maintenance and upgrading works, and preparations for redeployment. These hands‑on operations were carried out in one of the world’s most energetic tidal sites – safely, efficiently and without leaving site. The technical capability and operational professionalism reflects how far the sector has advanced. Subsea turbine servicing is becoming routine offshore practice, a key step to lowering costs and de-risking tidal energy as it moves toward larger-scale commercial deployment.

Across several days offshore, we were able to observe a packed programme of activity including subsea cable operations, turbine recovery, maintenance and upgrading works, and preparations for redeployment. These hands‑on operations were carried out in one of the world’s most energetic tidal sites – safely, efficiently and without leaving site. The technical capability and operational professionalism reflects how far the sector has advanced. Subsea turbine servicing is becoming routine offshore practice, a key step to lowering costs and de-risking tidal energy as it moves toward larger-scale commercial deployment.

A strong health and safety culture was evident throughout the campaign. From hazard identification and risk assessment to toolbox talks and procedural briefings, communication was clear, risk ownership was visible and the pace never compromised safety. The scale and complexity of the operations highlighted the benefits of having colleagues and contractors with experience drawn from diverse and more mature offshore industries. It was encouraging to see that the level of preparation and adaptability on display has become standard practice in tidal energy operations, shaped by years of experience and shared practice across the sector.

Innovation grounded in real‑world lessons

Another encouraging aspect of the visit was seeing the practical application of innovations that are already influencing the next generation of tidal technologies. For example:

- data from environmental monitoring platforms being used to strengthen evidence for seal‑collision avoidance;

- laser‑guided systems supporting rapid fastening of subsea frames; and

- the use of distributed acoustic sensing (DAS) for fault detection and localisation – an approach we are also exploring for use at EMEC.

These developments build on early demonstration work carried out at EMEC where previous iterations of both the Andritz Hydro Hammerfest and Proteus (then known as ‘Atlantis’) turbines were tested. Seeing the way those early lessons have shaped current systems, and are helping pave the way for scalable, commercial arrays, was grounding and inspiring.

Collaboration that strengthens the entire sector

A hugely valuable aspect of the visit for me was the space it created for open discussion. Across the tidal sector, partners are continually balancing the protection of intellectual property with the understanding that collaboration is essential to move the whole sector closer to delivering bankable, large‑scale tidal energy projects. This visit provided another welcome opportunity to exchange insights and strengthen that shared understanding.

During our time offshore, we discussed what the sector needs as it moves toward larger‑scale tidal arrays. For a 200 MW‑plus future to become reality, the pool of experienced personnel, the body of proven operating procedures and the availability of reliable subsea methodologies must continue to grow.

Incremental progress = long-term impact

Working at an innovation centre we can get absorbed in the challenges of day‑to‑day problem solving. Seeing how technologies that first entered the water at EMEC have evolved into the robust machines operating today was a powerful reminder of the long‑term value of a test site and the impact of the work we do.

It was equally motivating to see how new tools, data systems and operational methods are emerging from real‑world experience in the water, and how EMEC can continue supporting that evolution through testing, shared learning and collaborative innovation.

Since operations began, MeyGen has generated more than 84 GWh of electricity (as at Nov 2025, see latest generation figures here), including a record‑breaking month in 2025 when the AR1500 turbine delivered 372 MWh. Achievements like these signal what is possible when strong engineering, consistent operational learning and shared ambition come together.

Looking ahead

As the sector moves from R&D towards early commercialisation, the collaborative spirit demonstrated during this visit will be fundamental. To help accelerate the sector’s progression from individual device to array deployments, EMEC is actively pursuing the expansion of its Fall of Warness tidal test site to support this transition. EMEC looks forward to continuing to work with partners across the industry including tidal developers, supply chain companies, academia and public‑sector collaborators to advance the knowledge base, tackle shared challenges and build the foundations for a thriving tidal energy sector.

A huge thank‑you again to the MeyGen and Proteus teams for welcoming us onboard and for their openness throughout. The visit was an energising end to the year and a powerful reminder of the collective progress the sector is making and the promise that lies ahead.

Heather Turnbull

Senior Technical Project Manager

EMEC